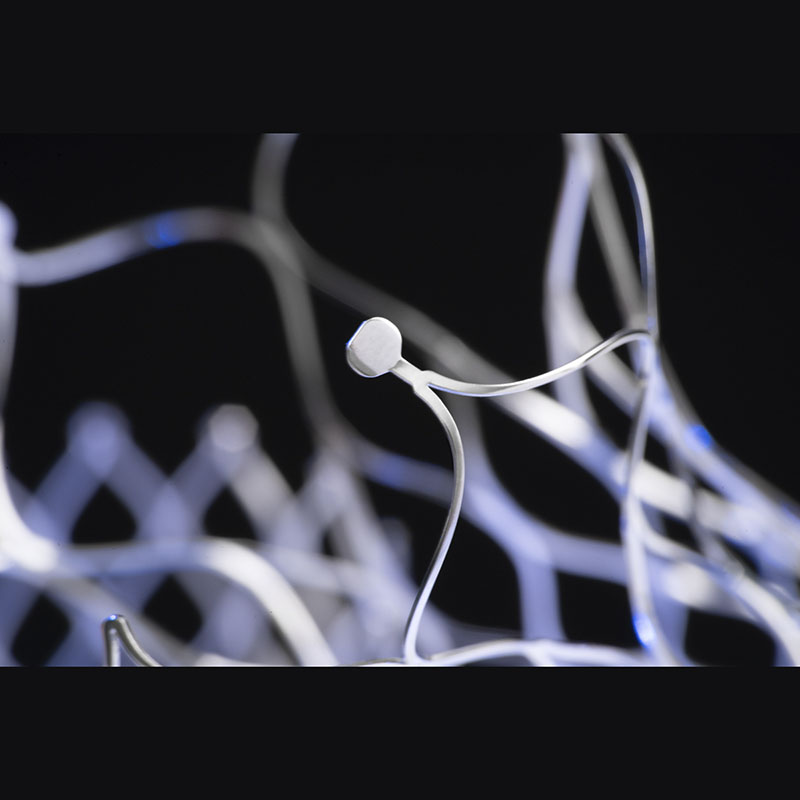

Likarolo tsa bongaka tsa tšepe tse nang le li-stents tsa nitinol le sistimi ea phepelo ea li-coil tse senyehang

Prototyping ea Karabelo e potlakileng

Theknoloji ea Laser

Theknoloji ea ho Fella Bokaholimo

Parylene & PTFE Coating Technology

Centerless Profile Grinding

Ho Honyela ha Mocheso

Microassembly

Litšebeletso tsa Lab ea liteko

● Coronary le neuro stents.

● Liforeimi tsa li-valve tsa pelo.

● Li-peripheral arterial stents.

● Likarolo tsa endovascular aneurysm.

● Delivery system le catheter component&.

● Li-stents tsa Gastroenterology.

Li-Stent & Nitinol Components

| Lintho tse bonahalang | Nitinol/ Stainless steel/ Co-Cr /… |

| Boemo | Ho nepahala ha bophara ba Strut: ± 0.003mm |

| Kalafo ea Mocheso | Kalafo e ntšo / e putsoa / e khanyang ea blue oxide bakeng sa likarolo tsa nitinol Phekolo ea vacuum bakeng sa tšepe e sa hloekang le li-stents tsa Co-Cr |

| Qetello ea Bokaholimo | ● Microblasting/chemical etching and polishing/ Ho bentsha ka mechine ● Bobeli bo ka hare le bokantle ba ka ntle bo ka etsoa electropolished |

Sistimi ea thomello

| Lintho tse bonahalang | Nitinol/ Tshipi e senang tshepe |

| Ho khaola Laser | Femtosecond OD≥0.2mm |

| Ho sila | Li-multi-tapered grinds, li-taper grinds tse telele bakeng sa li-tubing le lithapo |

| Welding | Laser welding/Soldering/Plasma welding Motsoako o fapaneng oa lithapo/tubing/coil |

| Liaparo | PTFE/Parylene |

Ho chesoa ka laser

● Automated laser welding bakeng sa lisebelisoa tsa bongaka le likaroloana, bonyane ba bophara ba sebaka se senyenyane ka ho fetisisa se ka fihla ho 0.0030".

● Ho chesoa ha litšepe tse sa tšoaneng.

Ho itšeha ka laser

● Ts'ebetso e se nang mabitso, bophara bo fokolang ba ho itšeha: 0.001".

● Ho sebetsana le mehaho e sa tloaelehang, ho pheta-pheta ho nepahetseng ho ka fihla ho ± 0.0001".

Phekolo ea mocheso

● Mocheso o nepahetseng oa phekolo ea mocheso le taolo ea sebopeho li netefatsa mocheso oa phetoho oa mohato o hlokoang ke sehlahisoa, kahoo o finyella litlhoko tsa ts'ebetso ea lisebelisoa tsa bongaka tse kentsoeng ka nickel-titanium.

Ho belisoa ka motlakase

● Ho bentša ntle le ho kopana.

● Bokhopo ba libaka tse ka hare le tsa ka ntle: Ra≤0.05μm, e phahametseng karolelano ea indasteri ka 0.2μm.

● Tsamaiso ea boleng ba ISO13485.

● E na le lisebelisoa tse tsoetseng pele ho netefatsa hore boleng ba sehlahisoa bo kopana le litlhoko tsa lisebelisoa tsa bongaka.